It is a sensor based on a photodetector whose task is to detect the intensity of the flame. Based on this, the sensor detects a flame and the controller proceeds to the appropriate procedure (e.g. lighting up). Most often used for boilers with automatic firing. Make sure that the sensor is not covered or dirty as this may prevent proper operation of the boiler.

The sensor is designed to work with boilers with both screw and piston feeders. It is used to check the position of the tray to detect jams or damage. The use of a feeder position sensor in a boiler with a piston (drawer) feeder enables precise administration of a single dose of fuel. It also helps prevent embers from flowing back into the basket or overheating the gearmotor. In the case of the screw feeder, the sensor mainly serves as an additional protection for the feeder motor in the event of its jamming. It consists of a reed switch and a magnet.

The weather sensor is used to regulate the temperature of the Central Heating Boiler or mixer based on the external temperature. Based on the sensor readings, the controller adjusts the set temperature of the system up or down. With a properly configured heating curve (temperature range) in the controller menu, the use of this sensor can help avoid excessively high indoor temperatures when it is warm outside or too low temperatures when it is cold, affecting user comfort. The correct use of the sensor involves the controller increasing the setpoint when the outside temperature decreases and decreasing it when the temperature rises. The sensor is typically mounted on the north side of the building at a height of about 2 meters. The measuring element of the weather sensor is the DS18B20, which sends a digital signal to the controller using the 1-Wire protocol.

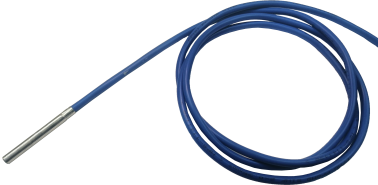

The sensor is used to measure the current temperature of the hot utility water tank (DHW). Used for both screw and piston feeders. Its task is to inform about too high temperature of the feeder. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. It is mounted on the inlet pipe to the water tank. In older types of regulators, DHW sensors with a digital measuring element DS18B20 were used.

A sensor designed to signal the opening of the cover of the Central Heating Boiler ashtray. It consists of two parts: a contactron sensor and a magnet. Bringing them close together causes the circuit to close. The opening of the ashtray interrupts the circuit, which the controller signals with an alarm.

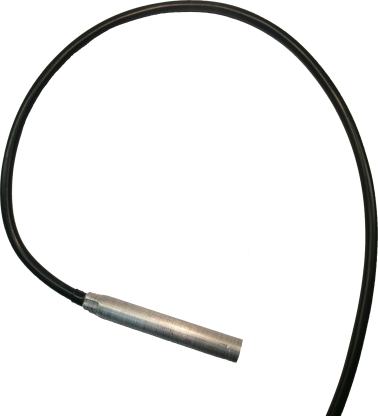

The sensor is used to measure the current feeder temperature. Used for both screw and piston feeders. Its task is to inform about too high temperature of the feeder. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. It is mounted on the feeder pipe. When working with a pellet boiler, it acts as a feeder sensor.

The sensor is used to measure the current temperature in a given mixer circuit. Its task is to inform about too high circulation temperature. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. Most often it is mounted on the pipe supplying the circuit (e.g. radiator, floor installation).

The sensor is used to measure the current temperature in the central heating boiler. The measuring element is quite well-known and popular KTY 21-810. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. Most often it is mounted on the pipe at the exit of the boiler.

The purpose of this sensor is to measure the temperature of flue gas flowing into the chimney. The element is used to improve the operation of the heating system to reduce heat loss. Thanks to the temperature measured by this sensor, the controller can adjust the operating parameters accordingly. It is mounted in the flue. The sensor is used as an additional option, it is not necessary for the proper operation of the boiler.

Emergency thermostat (self-acting)

Element designed for mechanical protection of the boiler. Its purpose is to disconnect the feeder or blower supply circuit as a result of too high temperature in the boiler. It works on the principle of disconnecting contact. The contacts disconnect when a certain (alarm) temperature is exceeded, which results in breaking the circuit. It is an automatic element, i.e. when the temperature drops below a certain threshold (usually 60 ˚C), the thermostat contacts close again. This thermostat is available in a tube or a box.

Element designed for mechanical protection of the boiler. Its purpose is to disconnect the circuit supplying the feeder and the blower as a result of too high temperature in the boiler. It works on the principle of disconnecting contact. The contacts disconnect when a certain (alarm) temperature is exceeded, which results in breaking the circuit. It is not possible to close the contacts automatically, even when the boiler temperature drops. It must be done by the boiler user using a special button. The thermostat is in the form of a metal box with a button.

The Krypton OP temperature controller is designed to control the operation of the central heating boiler. with oil burner; The device has an output for connecting a remote control, which further increases its usability. The remote panel in the room, after reaching the desired temperature, lowers the boiler temperature setting by the previously set value.

The PROTON BUFOR temperature controller is designed to control the operation of central heating boilers. V CLASS equipped with a blower or exhaust fan. It stabilizes its temperature by means of smooth regulation of fan speed, blows the boiler (in order to remove excess gases generated in the combustion process) and protects the central heating system against boiling water. The advantage of this regulator is that in addition to operating the central heating pump, it is also possible to control an additional pump, which can be used as a pump for loading the DHW tank or Buffer, which makes it easier to adapt the device to the user's needs.

The Krypton P regulator is a modern regulator for dust-charged boilers. Different types of housings in which the regulator is available allow the regulator to be mounted on the boiler or fuel tank, on the wall in the boiler room, under the boiler, in the control cabinet, on the rail. The Krypton P microprocessor controller is designed to control the operation of the blower and the circulation pump in central heating systems, it has an output for connecting a remote control. The SW2 version of the controller is designed to work with high-power boilers, which supports single-phase devices, including a feeder and a blower up to 0.55kW.

IRYD 620 is a regulator designed to control the operation of a central heating boiler with a pellet burner. The regulator controls an extensive heating installation. A specially designed menu enables gradual activation of subsequent functions and capabilities of the controller. This regulator has a special pid fuzzy logic algorithm that can smoothly select the appropriate fuel doses depending on the installation load and the type of fuel. The regulator continuously controls the operation of the blower by selecting the appropriate amount of fuel for a given blower speed. All this, combined with the automatic firing up and shutdown of the boiler, allows you to save on the amount of fuel burned, and thus it has a beneficial effect on the natural environment. The regulator can support additional expansion modules operating in the RS 485 standard, which allow for a significant extension of the heating installation and convenience of use. Such devices include a room panel, an internet module and a mixing valve module (possibility of connecting 6 mixers at the same time). Thanks to the support of the optical flame sensor and the flue gas temperature sensor, this regulator can work with virtually any pellet burner, both with 1 fuel feeder and with 2 feeders (auxiliary feeder). It supports self-cleaning burners with a moving grate as well as simple burners without optics and automatic cleaning. In addition, it has a function that allows combustion on an additional grate as well as the operation of the burner without flame control in emergency mode. The whole system is equipped with a number of additional sensors (e.g. external temperature, room panels) that allows the boiler to be turned off if the given heating circuits are heated up.Thus, the boiler with the iridium 620 regulator will ignite itself and start heating the circuit that will require it at the moment. As one of the few regulators, Iryd 620 has the ability to work with a heat buffer, which is more and more often used in modern central heating installations. The whole thing is dressed in a legible color display and proven electronic solutions that allow for pleasant use of the regulator for many years.

The PROTON BUFOR temperature controller is designed to control the operation of central heating boilers. V CLASS equipped with a blower or exhaust fan. It stabilizes its temperature by means of smooth regulation of fan speed, blows the boiler (in order to remove excess gases generated in the combustion process) and protects the central heating system against boiling water. The advantage of this regulator is that in addition to operating the central heating pump, it is also possible to control an additional pump, which can be used as a pump for loading the DHW tank or Buffer, which makes it easier to adapt the device to the user's needs.

Sterownik IRYD RTZ PID 601 SW1 i SW2

IRYD RTZ Pid Fuzzy Logic KOLOR is a regulator designed to control the operation of a central heating boiler with a screw or piston feeder (with a feeder position sensor). The regulator controls an extensive heating installation. A specially designed menu enables gradual activation of subsequent functions and capabilities of the regulator. This regulator has a special pid fuzzy logic work algorithm, which, after defining the maximum and minimum boiler power by the user, can smoothly select the appropriate doses of fuel depending on the load of the installation and the type of fuel. The regulator continuously controls the operation of the blower by selecting the appropriate amount of fuel for a given blower speed. In addition, this version is equipped with an additional pid algorithm that influences the flue gas temperature and regulates the boiler power so that the flue gas temperature value does not exceed the maximum value set by the user. These modern control algorithms allow you to save on the amount of fuel burned, and thus it has a beneficial effect on the natural environment. RS 232 ProND communication was used in Iryd RTZ PID RS, which allowed to extend the possibilities of its operation. RS232 ProND allows, among other things, to connect the controller to the LAN module. This communication, compared to 1 - Wire, allowed to increase the scope of functions used for remote control of the regulator. SW1 and SW2 controllers are designed to work with high power boilers. The SW1 version is designed for boilers with a three-phase feeder with a power of up to 4kW and a blower up to 0.55kW, while the SW2 version supports single-phase devices, including a feeder and blower up to 0.55kW.

Controller Titanic 3 SW1 i SW2

Titanic 3 is a regulator designed to control the operation of a central heating boiler with a screw or piston feeder (with a feeder position sensor). This regulator has the option of weather control. After connecting an additional external temperature sensor, the regulator calculates the boiler setting according to the heating curve set by the user. In addition, the Titanic regulator supports remote control - REMOTE CONTROL or room thermostat, to increase the comfort of using the controller, it is possible to stabilize the temperature in the room by using these additional devices. SW1 and SW2 controllers are designed to work with high power boilers. The SW1 version is designed for boilers with a three-phase feeder with a power of up to 4kW and a blower up to 0.55kW, while the SW2 version supports single-phase devices, including a feeder and blower up to 0.55kW.

Krypton BP microprocessor temperature controller is designed to control the operation of the central heating boiler. charging hopper with an air jacket equipped with a blower ventilating the furnace; stabilizes its temperature by smooth blower speed control (PID algorithm).Krypton BP controls the operation of a hot air blower and two high-power blowers (550W) to aerate the furnace. The use of this regulator improves the ergonomics of use: there is no need to interfere with the settings of the controller when the fuel is changed. The device has an output for connecting a remote control which further increases its usability.