In this group, there is equipment used for collaboration with the controller. The accessories include, among others, sensors that are an important part of the controller, without which it is unable to function properly. They are a fundamental part of the set or can be an additional option to expand the capabilities of the controller. All necessary technical information about the sensors and their purpose is provided here.

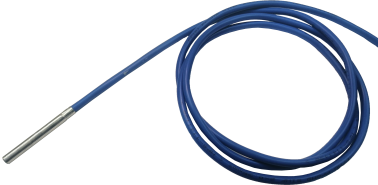

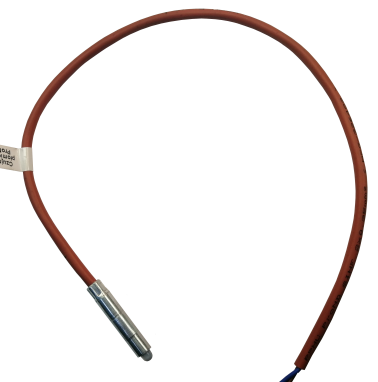

The sensor is used to measure the current feeder temperature. Used for both screw and piston feeders. Its task is to inform about too high temperature of the feeder. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. It is mounted on the feeder pipe. When working with a pellet boiler, it acts as a feeder sensor.

The sensor is used to measure the current temperature in the central heating boiler. The measuring element is quite well-known and popular KTY 21-810. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. Most often it is mounted on the pipe at the exit of the boiler.

It is a sensor based on a photodetector whose task is to detect the intensity of the flame. Based on this, the sensor detects a flame and the controller proceeds to the appropriate procedure (e.g. lighting up). Most often used for boilers with automatic firing. Make sure that the sensor is not covered or dirty as this may prevent proper operation of the boiler.

The weather sensor is used to regulate the temperature of the Central Heating Boiler or mixer based on the external temperature. Based on the sensor readings, the controller adjusts the set temperature of the system up or down. With a properly configured heating curve (temperature range) in the controller menu, the use of this sensor can help avoid excessively high indoor temperatures when it is warm outside or too low temperatures when it is cold, affecting user comfort. The correct use of the sensor involves the controller increasing the setpoint when the outside temperature decreases and decreasing it when the temperature rises. The sensor is typically mounted on the north side of the building at a height of about 2 meters. The measuring element of the weather sensor is the DS18B20, which sends a digital signal to the controller using the 1-Wire protocol.

The sensor is used to measure the current temperature of the hot utility water tank (DHW). Used for both screw and piston feeders. Its task is to inform about too high temperature of the feeder. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. It is mounted on the inlet pipe to the water tank. In older types of regulators, DHW sensors with a digital measuring element DS18B20 were used.

Emergency thermostat (self-acting)

Element designed for mechanical protection of the boiler. Its purpose is to disconnect the feeder or blower supply circuit as a result of too high temperature in the boiler. It works on the principle of disconnecting contact. The contacts disconnect when a certain (alarm) temperature is exceeded, which results in breaking the circuit. It is an automatic element, i.e. when the temperature drops below a certain threshold (usually 60 ˚C), the thermostat contacts close again. This thermostat is available in a tube or a box.

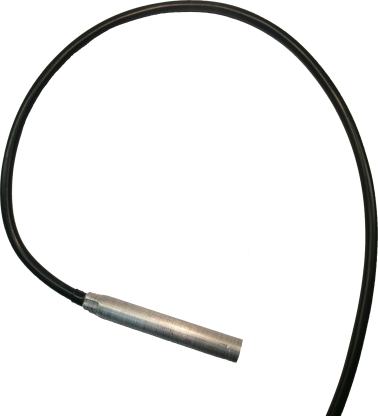

The purpose of this sensor is to measure the temperature of flue gas flowing into the chimney. The element is used to improve the operation of the heating system to reduce heat loss. Thanks to the temperature measured by this sensor, the controller can adjust the operating parameters accordingly. It is mounted in the flue. The sensor is used as an additional option, it is not necessary for the proper operation of the boiler.

The sensor is designed to work with boilers with both screw and piston feeders. It is used to check the position of the tray to detect jams or damage. The use of a feeder position sensor in a boiler with a piston (drawer) feeder enables precise administration of a single dose of fuel. It also helps prevent embers from flowing back into the basket or overheating the gearmotor. In the case of the screw feeder, the sensor mainly serves as an additional protection for the feeder motor in the event of its jamming. It consists of a reed switch and a magnet.

A sensor designed to signal the opening of the cover of the Central Heating Boiler ashtray. It consists of two parts: a contactron sensor and a magnet. Bringing them close together causes the circuit to close. The opening of the ashtray interrupts the circuit, which the controller signals with an alarm.

The sensor is used to measure the current temperature in a given mixer circuit. Its task is to inform about too high circulation temperature. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. Most often it is mounted on the pipe supplying the circuit (e.g. radiator, floor installation).

Element designed for mechanical protection of the boiler. Its purpose is to disconnect the circuit supplying the feeder and the blower as a result of too high temperature in the boiler. It works on the principle of disconnecting contact. The contacts disconnect when a certain (alarm) temperature is exceeded, which results in breaking the circuit. It is not possible to close the contacts automatically, even when the boiler temperature drops. It must be done by the boiler user using a special button. The thermostat is in the form of a metal box with a button.