The sensor is designed to work with boilers with both screw and piston feeders. It is used to check the position of the tray to detect jams or damage. The use of a feeder position sensor in a boiler with a piston (drawer) feeder enables precise administration of a single dose of fuel. It also helps prevent embers from flowing back into the basket or overheating the gearmotor. In the case of the screw feeder, the sensor mainly serves as an additional protection for the feeder motor in the event of its jamming. It consists of a reed switch and a magnet.

The LAN module is intended for remote control of the central heating boiler operation regulator. by ProND with an RJ12 connector for connecting the PILOT room panel (1-Wire communication) or with an RJ12 connector for RS485, RS232 communication. The regulator works with a wide range of ProND products. The possibilities and application depend on the controller to which this module is connected.'

A sensor designed to signal the opening of the cover of the Central Heating Boiler ashtray. It consists of two parts: a contactron sensor and a magnet. Bringing them close together causes the circuit to close. The opening of the ashtray interrupts the circuit, which the controller signals with an alarm.

The sensor is used to measure the current temperature in a given mixer circuit. Its task is to inform about too high circulation temperature. The measuring element is quite well-known and popular KTY 81-210. This element works on the principle of changing the resistance under the influence of temperature changes. This information is then processed by the controller. Most often it is mounted on the pipe supplying the circuit (e.g. radiator, floor installation).

The MZM-50 mixing valve module cooperates ONLY with ProND controllers equipped with the RS485 ProND STANDARD for connecting additional expansion modules, e.g. Iryd 610. The module is designed to control the actuator with a mixing valve pump in central heating installations. In addition, a room thermostat or a PILOT can be connected to the regulator, which further increases its functionality. The device communicates with the controller via the RJ 12 socket marked as "RS 485 interface". You only need to connect them with a suitable cable.

Room control panel PILOT G 906

The PILOT G 906 remote control panel is a modern and functional device cooperating with PROND regulators equipped with an RJ12 (1-Wire) or RJ45 (RS 485 ProND) socket for remote control connection. It has a modern casing with a large touchscreen display. The G 906 PILOT enables operation in two communication standards: 1-Wire (designed for controllers manufactured since 2003) or RS 485 ProND (designed for the latest controllers such as Iryd 610).The functionality of the panel varies depending on the selected standard. PILOT G enables remote monitoring of the operation of devices such as a feeder, blower or central heating pump. In addition, it is possible to remotely change the boiler / circuit settings, DHW settings, operating mode and has the function of a room thermostat (turning off the circulation pump when the room is heated). It has built-in time zones (temperature programming for the whole week) and a vacation mode.

Element designed for mechanical protection of the boiler. Its purpose is to disconnect the circuit supplying the feeder and the blower as a result of too high temperature in the boiler. It works on the principle of disconnecting contact. The contacts disconnect when a certain (alarm) temperature is exceeded, which results in breaking the circuit. It is not possible to close the contacts automatically, even when the boiler temperature drops. It must be done by the boiler user using a special button. The thermostat is in the form of a metal box with a button.

Sterownik IRYD RTZ PID 601 SW1 i SW2

IRYD RTZ Pid Fuzzy Logic KOLOR is a regulator designed to control the operation of a central heating boiler with a screw or piston feeder (with a feeder position sensor). The regulator controls an extensive heating installation. A specially designed menu enables gradual activation of subsequent functions and capabilities of the regulator. This regulator has a special pid fuzzy logic work algorithm, which, after defining the maximum and minimum boiler power by the user, can smoothly select the appropriate doses of fuel depending on the load of the installation and the type of fuel. The regulator continuously controls the operation of the blower by selecting the appropriate amount of fuel for a given blower speed. In addition, this version is equipped with an additional pid algorithm that influences the flue gas temperature and regulates the boiler power so that the flue gas temperature value does not exceed the maximum value set by the user. These modern control algorithms allow you to save on the amount of fuel burned, and thus it has a beneficial effect on the natural environment. RS 232 ProND communication was used in Iryd RTZ PID RS, which allowed to extend the possibilities of its operation. RS232 ProND allows, among other things, to connect the controller to the LAN module. This communication, compared to 1 - Wire, allowed to increase the scope of functions used for remote control of the regulator. SW1 and SW2 controllers are designed to work with high power boilers. The SW1 version is designed for boilers with a three-phase feeder with a power of up to 4kW and a blower up to 0.55kW, while the SW2 version supports single-phase devices, including a feeder and blower up to 0.55kW.

REG 1 blower speed controller is a universal controller specifically designed for different types of blowers powered from the mains voltage of 230V. Adjusting the minimum rotations allows to use the entire useful range of characteristics of the blower. The device is used in systems where there is a need to enhance a single-phase motor control system with the adjustment of its rotations.

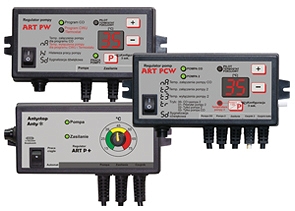

ART P+ microprocessor controller is a universal controller for the C.H. pump. The ease of use and reliability make it the most widely used controller in the C.H. systems without an air-supply.

Description: ART PDW controller is a controller for fine coal and hopper boilers and at the same time a successor of the ART PD controller. ART PDW microprocessor controller is designed to control the blower and circulating pump in the C.H. systems where there is no need to adjust the speed of the fan (adjustable air inlet by the aperture of the blower). It has an output for connecting a remote control.

ART ZW microprocessor controller is a controller designed to control the actuator with the mixing valve pump. In addition, a room thermostat or a remote control can be connected to the controller, which further enhances its functionality. The ART ZW controller allows to extend the features of the existing heating system at low cost without replacing the controller controlling the operation of the boiler.

IRYD RTZ PID 602 is a controller designed to control the operation of a central heating boiler with a screw feeder or piston feeder (with a feeder position sensor). The controller controls an extensive heating installation. A specially designed menu enables gradual activation of further functions and possibilities of the regulator. In addition, a large touch screen provides greater convenience in using the device.

This regulator has a special fuzzy logic pid operation algorithm, which, after the user specifies the maximum and minimum boiler power, can smoothly select the appropriate fuel doses depending on the load on the installation and the type of fuel.The controller continuously controls the blower operation by selecting the appropriate amount of fuel for the given blower speed. In addition, this version is equipped with an additional pid algorithm influencing the flue gas temperature, regulating the boiler power so that the flue gas temperature does not exceed the maximum value set by the user. These modern control algorithms allow you to save on the amount of fuel burned, and thus have a beneficial effect on the natural environment. Additionally, RS 232 communication was used, thanks to which it is possible to expand the boiler control system with the MI-95 internet module. The controller also has a USB socket that allows for updating the software.

The regulator Krypton B is a modern regulator for fine coal and hopper boilers with an jacket. It is used in hot air heating systems for halls and buildings. Krypton B microprocessor controller is used to control the operation of two blowers supplying air to a burner and a hot air blower. It has an output for connecting a remote control which further enhances its usability. The controller continuously and automatically controls the blower and maintains a pre-set boiler temperature at a constant level. This solution ensures that there are no rapid temperature changes in the boiler. The use of this controller improves the operation ergonomics: no need to interfere in the settings of the driver in case of a change of fuel.

Room control panel PILOT G 904

The PILOT G 904 remote control panel is a modern and functional device cooperating with PROND regulators equipped with an RJ12 (1-Wire) or RJ45 (RS 485 ProND) socket for remote control connection. It has a modern housing with a color display and illuminated keys. The G 904 PILOT enables operation in two communication standards: 1-Wire (designed for controllers manufactured since 2003) or RS 485 ProND (designed for the latest controllers such as Iryd 610, Iryd 620) The functionality of the panel varies depending on the selected standard. PILOT G enables remote monitoring of the operation of devices such as a feeder, blower or central heating pump. In addition, it is possible to remotely change the boiler / circuit settings, DHW settings, operating mode and has the function of a room thermostat (turning off the circulation pump when the room is heated). It has built-in time zones (temperature programming for the whole week) and a vacation mode.

The REG 2 blower speed regulator is a universal regulator designed for various types of blowers supplied from 230V mains voltage, the power of which does not exceed 200W. The device is used in systems where there is a need to expand the control system of a single-phase motor with the regulation of its rotation.

Argon 110 controller is a modern controller for boilers with an air jacket that support the feeding screw. It is used in hot air heating systems for halls and buildings. Argon 110 microprocessor controller is designed to control the blower supplying air to a burner, a feeding screw and two hot air blowers. It has an output for connecting a remote control which further enhances its usability.

ART C + microprocessor controller is a universal controller for the H.T.W. pump. The ease of use and reliability make it the most widely used controller in simple H.T.W. control systems.

IRYD 610 is a controller designed to control the operation of a central heating boiler with a feeding screw. The controller controls an extensive heating installation. A specially designed menu enables gradual activation of further functions and possibilities of the regulator. This regulator has a special fuzzy logic pid operation algorithm, which, after the user specifies the maximum and minimum boiler power, can smoothly select the appropriate fuel doses depending on the load on the installation and the type of fuel. The regulator controls the blower operation continuously by selecting the appropriate amount of fuel for the given blower speed. In addition, this version is equipped with an additional pid algorithm influencing the flue gas temperature, regulating the boiler power so that the flue gas temperature does not exceed the maximum value set by the user. These modern control algorithms allow you to save on the amount of fuel burned, and thus have a beneficial effect on the natural environment. Additionally, up to 5 mixing valve control modules, an internet module and a room panel can be connected to the regulator, which allows for a significant expansion of the heating system.

YETI controller is a universal controller for fine coal and hopper boilers. YETI microprocessor controller is designed to control the blower and circulating pumps in the C.H. systems. It has an output for connecting a remote control.