Description

IRYD MZ pid fuzzy logic controller is designed to control the operation of the C.H. fine coal and hopper boiler. The controller controls an extensive heating system. A specially designed menu allows to progressively activate further features or abilities of the controller. This controller has a special algorithm for the operation of pid fuzzy logic, which after determining by the user the maximum and minimum capacity of the boiler can smoothly select the blower speed, depending on the electrical load of the system and the type of fuel. In addition, this version has an additional algorithm pid, affecting the exhaust gas temperature and regulating the power of the boiler so that the value of the exhaust gas temperature does not exceed the maximum temperature pre-set by the user. These modern control algorithms allow to save on the amount of burned fuel, and which has a positive impact on the environment..

Language versions

Special features

Functions

- flexible adjustment of the boiler output (PID algorithm for the blower)

- control of a C.H. circulating pump

- controlling the pump that feeds the H.T.W. tank

- control of the second heating circuit, i.e. of the mixing valve pump or the pump for the underfloor heating

- control of the mixing valve actuator

- control of the circulating pump, which can be used in the H.T.W. circulation or C.H. circulation.

- supports two remote control systems or room thermostats (two independent circuits)

- the ability to control the weather-dependent temperature of the boiler and of the mixer circuit *

- weekly control of the C.H. circulation of the mixer/floor, C.T.W., C.H. circulation

- operation-modes: WINTER, SUMMER, PRIORITY, H.T.W., NO H.T.W.

- 5 sets of programmable parameters between which one can switch while using the controller.

- additional algorithm pid that monitors the exhaust gas temperature*

- an anti freezing feature below 5°C

- an anti-stop feature to prevent the stopping of pumps

* the weather sensor and the exhaust gas sensor must be purchased separately.

Versions

1S - Version for the installation on the boiler or next to the boiler on the wall, a panel at an angle, cables extending from the rear of the controller housing

0S - The high boiler version, where using the 1S case could have problems with the keys

2S - The 2S housing allows the assembly of some of the wiring under the insulation of the boiler. Inside there is an operating module mounted on the bus, which greatly simplifies installation and removal of the module

3S – The 3S housing, a version for mounting on the boiler or a tank with fuel; the holes in the bottom of the controller allow placing some of the wiring under the insulation of the boiler

1S FULL - The full 1S housing allows full assembly of some of the wiring under the insulation of the boiler, the panel is mounted in the front wall of the boiler

module + panel - working module and a panel, separately (without the metal casing). Special operator's panel with locks enables it to be mounted on the facade of the boiler. The working module has special locks with which it is mounted on 35mm DIN bus

Ps drawer type - a version for installation in its entirety under the insulation of the boiler. Sockets for connecting devices on the back of the case (at the back of the boiler), high-quality industrial connectors for installing sensors

Wersje wzmocnione

- wersja wzmocniona: dmuchawa 550W podajnik 250W pompy 250W dostępna w obudowach 1S, 1S pełnej, 0S

- wersja wzmocniona dmuchawa, podajnik pod stycznik: pod wyjście podajnik można podłączyć cewkę stycznika, dmuchawa wzmocniona 550W pompy 250W, dostępna w obudowach 1S, 1S pełnej, 0S

Regulator operating system

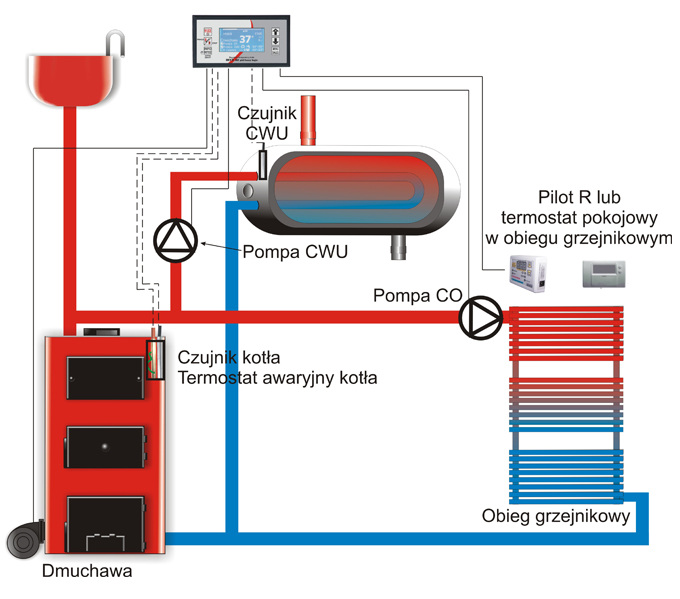

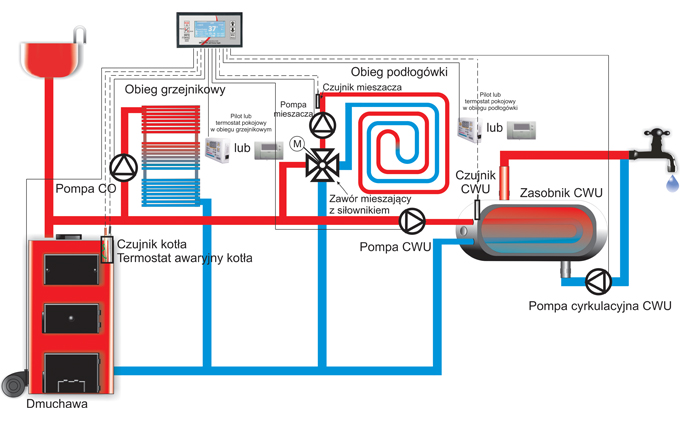

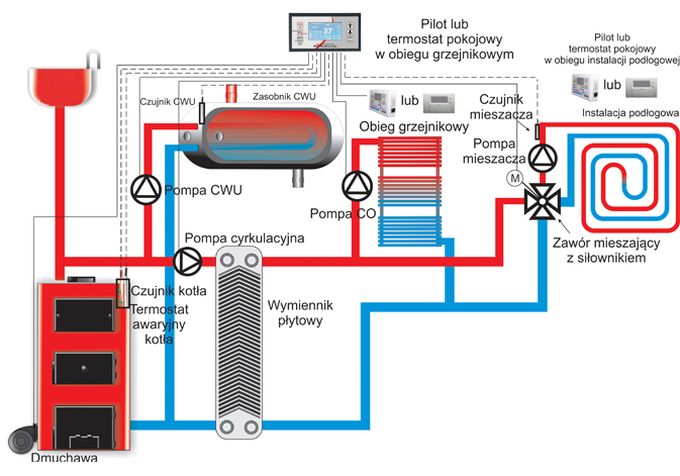

1. A standard configuration of the arrangement of a controller with the H.T.W. pump. In this installation, the C.H. pump supplies the system related to the heating of rooms. Pompa ładująca zasobnik CWU nagrzewa wodę wykorzystywaną w instalacji CWU. - The pump that supplies the H.T.W. tank heats the water used in the H.T.W.

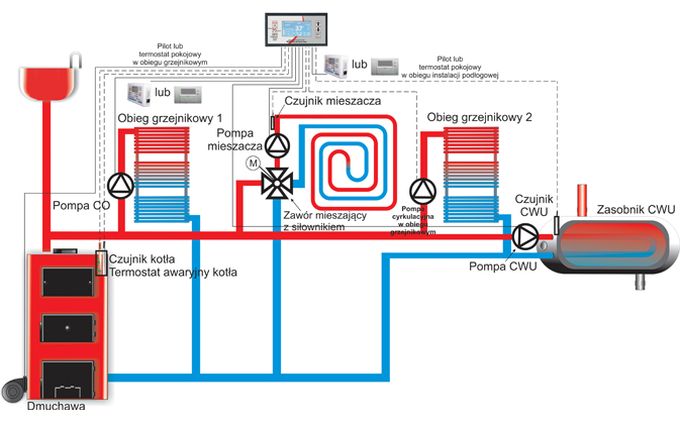

2. The system with a C.H. pump that supplies radiators, a mixer pump with a mixer controlled by an actuator in a floor circulation system, a pump supplying the H.T.W. tank, a circulating pump in the H.T.W. circulation.

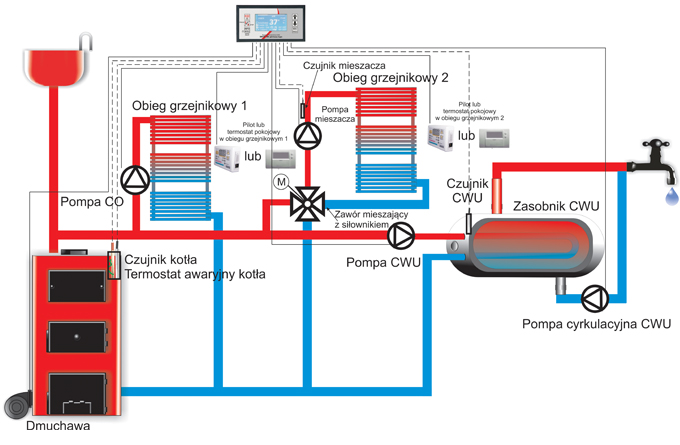

3. A system with a C.H. pump, radiator system circuit with a mixing valve actuator, a pump that supplies the H.T.W. tank, H.T.W. circulating pump

4. A system with a C.H. pump, a pump that supplies H.T.W. tank, H.T.W. circulating pump, a mixing valve with an actuator as returns from the system

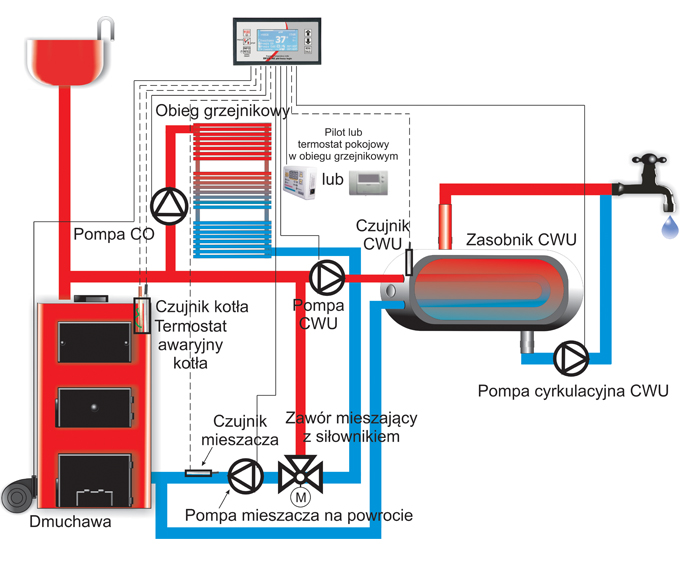

5. A system with a C.H. pump, floor heating circuit with a manual or a thermostat mixing valve, a pump supplying the H.TW. tank, H.T.W. circulating pump

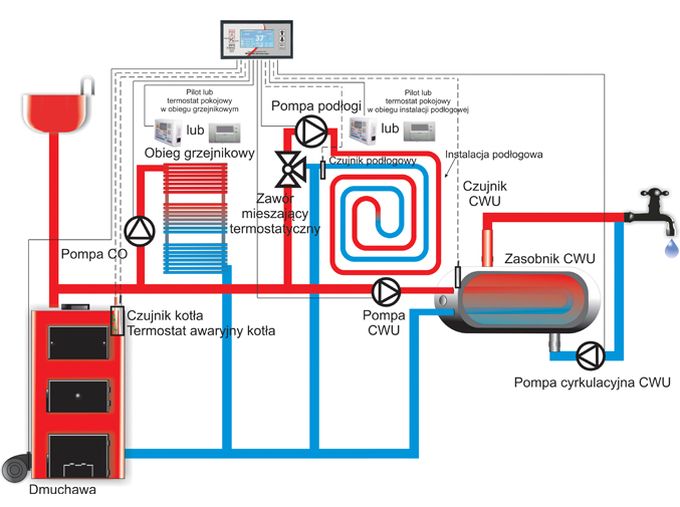

6. A system with a C.H. pump, underfloor heating circuit with a mixing valve actuator, a pump supplying the H.T.W. tank, a circulating pump supplying additional radiator circuit

7. A system with a C.H. pump, with underfloor heating circuit with a mixing valve actuator, with a pump supplying H.T.W. tank, a circulating pump supplying a plate heat exchanger